TYPE-I-8/16

High performance model, identifying abnormal parts and detect damage conditions

Applications

This product addresses the following needs.

- Accurate identification of the abnormal area and damage status.

| Measurement method | Continuous monitoring | |

|---|---|---|

| Diagnostic method | Vibration (overall value, frequency analysis) | |

| Data management | Cloud server | |

| Wireless sensor | Not supported | |

| Explosion-proof sensor | Available | |

| Operating condition | Input speed fluctuation | Available |

| Output load fluctuation | Available | |

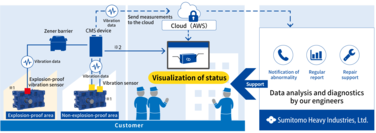

System configuration

Measurement data is transmitted via a mobile network. No troublesome cabling is required. Our engineers analyze data in the cloud and provide reports.

*1: The rotation speed and load signals can also be measured.

*2: When the diagnostic software (sold separately) is installed, you can manage the measurements on your PC without accessing to the cloud server.

Features

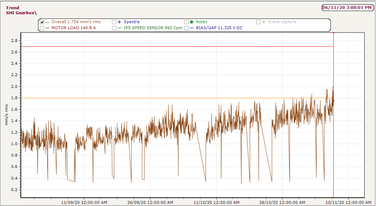

Early detection of abnormalities

Abnormalities can be detected before the failure by monitoring the trend of vibration values at characteristic frequencies through frequency analysis.

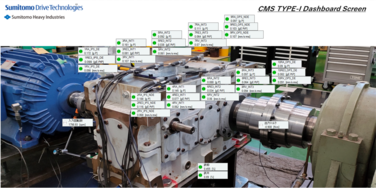

Identification of damaged parts and damage

Damaged parts and damage can be identified by analyzing the vibration values obtained from multiple sensors.

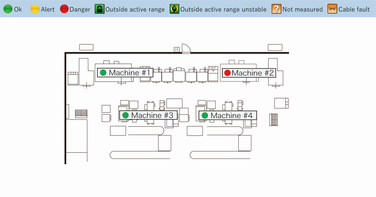

Integrated monitoring of multiple units

You can select either the 8-channel type or the 16-channel type according to the type of reducer and application.

Monitoring under complex operating conditions

Gearmotors can be monitored even if there is fluctuation in rotation speed or load.

Proposals based on detailed analysis by our engineers

Our engineers propose countermeasures based on precise analysis of the cloud data.

How to check diagnostic results

- The easy-to-understand dashboard screen allows you to monitor the statuses of gearboxes.

- A list of monitored gearboxes and their details can be reviewed.

- The trend values and frequency analysis results of each sensor are also available.

| Device | PC, tablet |

|---|

Integrated monitoring of equipment screen

Detailed confirmation screen

The trend of each sensor value