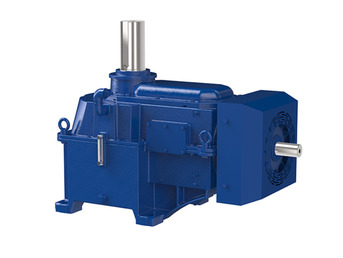

PARAMAX SFC Series for Cooling Fan

The reducer designed for cooling towers and air fin coolers, prioritizing high usability and suitability

- Optimized unit specifically to rotate the cooling fans of the wet cooling towers and air-cooled condensers.

- Installed shaft driven fun, for radiating heat around the gearbox, which becomes a pocket of airflow from output fun.

- 25° pressure angle gear with a thicker dedendum for higher strength is adopted. This achieved high load capacity and shock load resistance.

- Allowed one year continuous operation of unit by high gearbox rating.

*PARAMAX is a registered trademark of Sumitomo Heavy Industries, Ltd.

| Output Shaft | Solid Shaft |

| Output Shaft Direction | Vertical Upward, Vertical Downward |

| Mounting Method | Case Mount |

| Number of Sizes | 7 sizes |

| Reduction Ratio | 6.3 - 18 |

| Rated Torque | 10,000 - 44,000 N⋅m |

Features

Optimal selection

Developed as a dedicated reducer for cooling fan drives, allowing for optimal selection based on motor capacity.

Low noise

Achieves reducing 3-5 dB(A) noise value (compared to our conventional model) by minimizing peripheral speed and vibration.

Low vibration design

The structure is designed to be resistant to the effect of vibration by extending the bearing span of the fan drive shaft (low-speed shaft of gearbox).

In addition, by evenly arranging the mounting bolt holes with respect to the center of the fan drive shaft, the load from the fan to the mount surface during operation is equally transmitted, ensuring stability.

Flat mount design for easy handling

It features a flat mount surface without protrusions for easy handling and installation. Compact backstops, pump options, that can be equipped without changing mount base.

Thermally efficient design

Due to the gearbox location in a cooling tower, minimal airflow from the cooling tower fan reaches it. To maintain the optimal temperature of the gearbox under such an environment, SFC gearbox is designed with maximum heat dissipation in mind, with a maximized surface area and a high-efficiency gearbox cooling fan.

Easy maintenance

- Allowed one year continuous operation.

- Gearbox is drilled and tapped for attachment of external air breather and oil fill/drain.

- Internal gearbox inspection is possible without draining oil due to inspection cover location above operating oil level.

- Using internal splash oil lubrication, use of an oil pump and its periodic replacement is not required.

Abundant accessories

Accessories suitable for cooling tower applications are standardized.

[Standard Equipment] Integral cooling fan, oil seal hood (output shaft), oil gauge, and magnetic plug.

[Optional] Backstop*, oil heater, oil pump, flow switch, oil level switch, dust-free air breather, vibration sensor seat.

*Use of a backstop (optional) is to prevent reverse rotation of the cooling fan. Backstop uses the internal gear oil for lubrication. Grease lubrication type is also available.

Supporting inverter control

It supports variable operation using an environmentally friendly inverter control method.